Molly_b1

Molly_b1Adding the sides to the frame of ribs and a few stringers.

The boatbuilding took place in May 1979, in McAllen, Texas.

Daily high temperatures were in the mid 90 degrees F.

Epoxy set fast.

Molly_b1

Molly_b1

Adding the sides to the frame of ribs and a few stringers.

Molly_b2

Molly_b2

Sides done, adding the bottom.

Molly_b3

Molly_b3

All the bottom and side plywood on and ready for the first coat of epoxy paint.

Molly_b4

Molly_b4

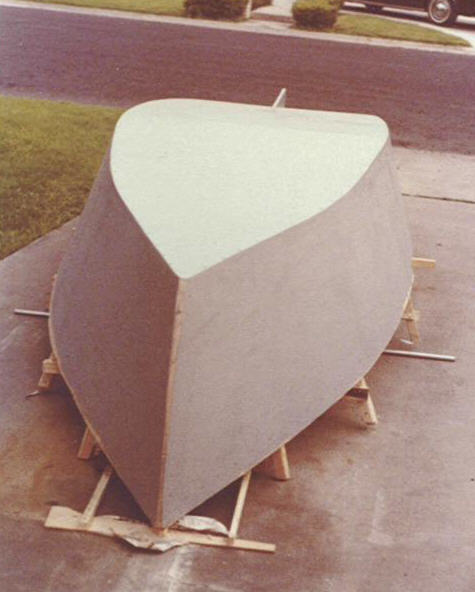

Hull ready to turn upright for the first time.

Molly_b5

Molly_b5

First turned upright. Basic hull form done.

Molly_b6

Molly_b6

Installing one of the bilge board cases.

The original plan specified a single centerboard.

I did not like the idea that a centerboard case would take up usable space

in the middle of the boat, so went the bilge board route.

Some years before, when in Massachusetts I had dropped in on Phil Bolger,

and he talked with me. At that time I asked him generally if bilge boards would work.

I called them two centerboards each set as far out as possible against the chines

as I did not know the term bilge boards at the time.

Phil said it would work but was dismayed at the extra cost of building 2 cases etc.

I decided since I wanted them, and it was my money, I would just do it.

Molly_b7

Molly_b7

Detail of bilge board cases.

Actually these are 2 pivoting centerboards, not mounted in the center.

Having 2 gives one the whole center of the boat to lounge in.

This is very helpful when the cuddy is installed. - - Cuddy picture

Molly_b8

Molly_b8

Bilge board cases installed.

Molly_b9

Molly_b9

The bracing for the deck is installed.

Molly_ba

Molly_ba

Sheer view, almost done.

Molly_bb

Molly_bb

All done, on the trailer and almost ready to go.

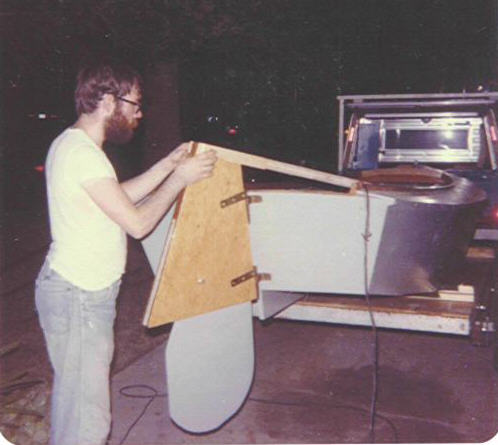

Molly_bc

Molly_bc

Last minute sailmaking.

This one was not done on time, and

the sail used on the maiden voyage was borrowed from a dingy.

Molly_bd

Molly_bd

Fitting the rudder.

In our shallow conditions in the bays and lagunas of South Texas it always pays to make a tip-up rudder.

Click here for the first launching of the Molly .

Small Boat building index page.