~ ~ ~ ~ ~ Simple Oars which use Pintles on which to pivot - Not using oarlocks ~ ~ ~ ~ ~

Why make oars by one of the following methods?

-

- They are less expensive than store-bought oars.

- They do not pivot. The blades stay perpendicular to horizontle. Making it easier to row.

- They stay put in the oarlocks, not moving in (together) or out. Making it easier to row.

model of a Nazare fishing boat, showing the oars

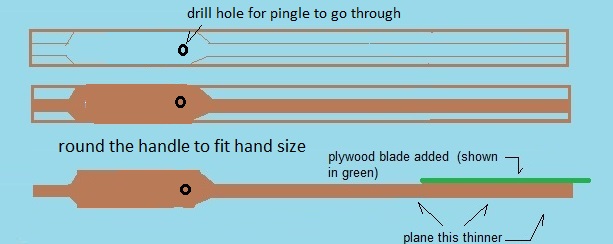

The oar is made of a 2x4 cut aas needed and thinned by the blade.

One needs to find a good 2x4 with no knots in the middle part.

It is best to find a light weight 2x4 - whitewood instead of southern yellow pine which although strong is very heavy.

Trim the 2x4 so it lies flat when used

Drill hole through for the pintle to poke up through

Add the blade of the oar loom to the tip.

(quarter inch thick plywood would work,

three eights thick plywood may be used for a more robust oar, but it will make the oar heavier )

-

When you are done constructing the oar, sand it smooth and paint it.

Once I painted my store-bought oars so they could easily be indentified as mine

and marked them so I couuld easily use them to determine how deep the water was in shallow areas.

- update - 7 November 2021

to the boatbuilding index page.

Return to the main page.